Reynolds designs equipment for the Adhesives, Sealants, Silicones and Caulks, Coatings and Paints,

Cosmetics and Pharmaceuticals, Inks and Pigments, Rubber, Polymers, Resins, and Foams, and Specialty Chemicals processing industries.

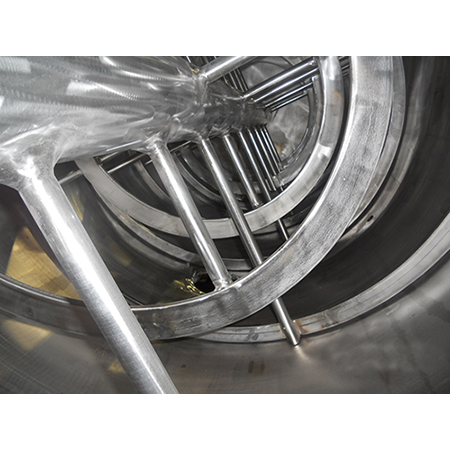

The Ribbon Blender has a unique shallow helix design that provides more left to right mixing and less centrifuging. The heavy-duty design provides for less ribbon loading and better quality mixing. A simple gas charged lift provides for safety and ease of lid opening. Our unique shaft seal design prevents leakage from either end of the blender.

| Model | HP | RPM | Total Volume (Ft3) | Working Volume (Ft3) | Dischange Valve Dia(In) |

|---|---|---|---|---|---|

| RRB-1 | 1 | 90 | 2 | 1.5 | 2 |

| RRB-2 | 2 | 60 | 4 | 3 | 3 |

| RRB-3 | 3 | 65 | 7 | 5 | 4 |

| RRB-5 | 5 | 60 | 12 | 10 | 4 |

| RRB-10 | 10 | 55 | 28 | 25 | 6 |

| RRB-15 | 15 | 40 | 55 | 50 | 6 |

| RRB-25 | 25 | 30 | 85 | 70 | 8 |

| RRB-30 | 30 | 25 | 115 | 100 | 8 |

| RRB-40 | 40 | 25 | 170 | 150 | 10 |

| RRB-50 | 50 | 25 | 250 | 225 | 10 |

| RRB-75 | 75 | 15 | 350 | 300 | 10 |

| RRB-100 | 100 | 20 | 450 | 400 | 10 |

| RRB-125 | 125 | 20 | 550 | 500 | 10 |

Reynolds Industries can perform lab test on customer's products. Our process experts will design a mixing system for your new product or to help with your existing mixing process. Our engineering team will determine a cost effective and long-lasting system to meet your processing requirements. Controls can be designed to fit with your existing control systems or new control systems can be designed for ease of operation.